Like Super Large Bore Extensions, you can use a kit to allow extension assembly in the field. Rigid extensions are also available. Z-Bore flows 370 CFM compared to 240 CFM on the Super Large Bore Valve System.

Flow Rate

240 (CFM)

Fits Valve Hole

13/16"

Hole Size Threaded

1/2" NPT

Special Inflator Needed

IN-80A/IN-95

Recommended Tire Sizes

20" up to 57"

Size Comparisons

.44" / 11.176mm

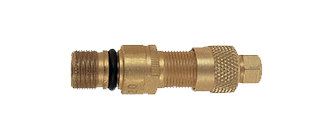

1. There are two basic spud designs:

a. The standard clamp-in spud (T-81/T-82)

b. The screw-in spud (C-100/C-155/C-134)

c. The angle screw-in spud (S-85)

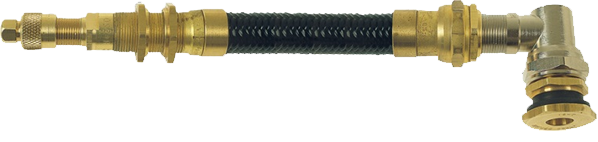

2. The next component is the swivel angle connector which threads onto the spud. There are different angles and lengths to accommodate the requirements of the customer. (R-525 Series)

3. The next component is a flexible extension which can be made in any length. (MT-3000 Series)

4. The core housing makes up the final component. It contains a Large Bore Valve Core for servicing the tire assembly for routine pressure checks and allows the complete core housing removal for the Super Large Bore application. It can also be installed in any of the previous components for a shorter valve. (R-520)

5. To maximize air flow, an IN-80A or an IN-95 inflator is used to remove the core housing during inflation and deflation. A kit to allow extension assembly in the field is available. Rigid extensions are also available. The Super Large Bore Valve System is more than three times faster than a Large Bore Valve.