WHAT CAN AN INTELLIGENT TIRE MANAGEMENT SYSTEM DO FOR YOU?

Haltec GO is Haltec Corporation’s emerging digital ecosystem designed to connect, monitor, and manage inflation and torque solutions across industries. It represents the next phase of Haltec’s precision and accountability mission, bringing decades of expertise in specialty valve systems, inflation devices, and torque tools into a fully connected digital environment.

HALTEC GO HELPS YOU CONTROL COSTS

Ensure you are getting the most value from your tire and rim assemblies with our consistent, high-quality products and services that keep your business running smoothly. Fleet managers, who oversee the deployment of numerous trucks, are aware of the intricacies of service and maintenance costs. That's why Haltec’s Bluetooth devices and app-based platform empower fleet managers to control, direct, and monitor all aspects of their fleet’s tires, maximizing their investment.

- Boost labor efficiency by over 50%

- Cut operating costs and reduce vehicle downtime

- Tailored solutions for both small and large commercial fleets

TACTICAL BENEFITS — MANAGE ASSETS NOT EXPENSES

Haltec GO enables highly accurate and real-time tire inspections across fleets of all sizes.

- Tire analysis in an instant — from rapid tread analysis to detailed tire condition data and automated pressure correction

- High-quality tire performance analysis, comparisons and reporting capabilities, while defects and abnormal wear are closely monitored and tracked

- Automatic, Bluetooth-enabled platform increases fleet inspection speed and accuracy

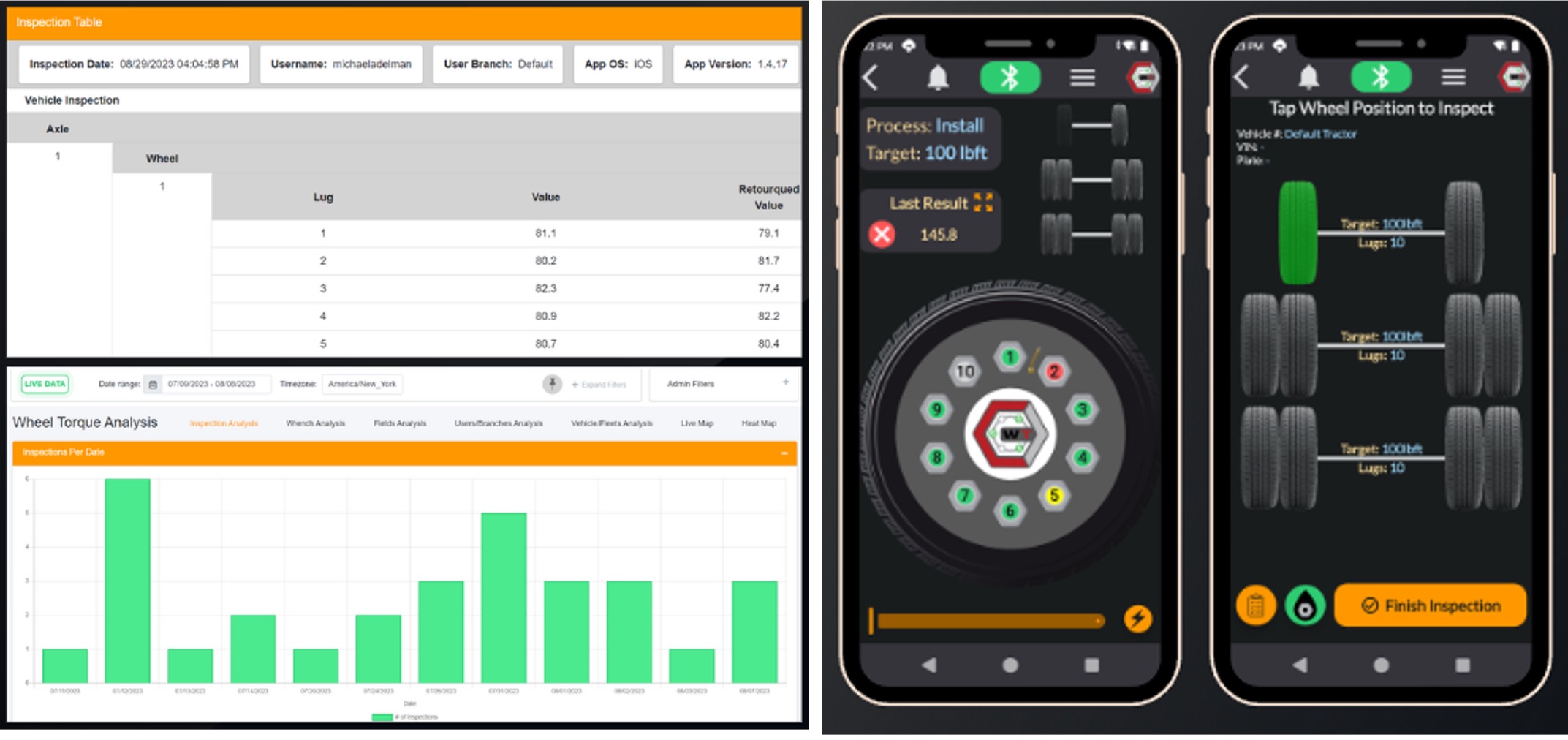

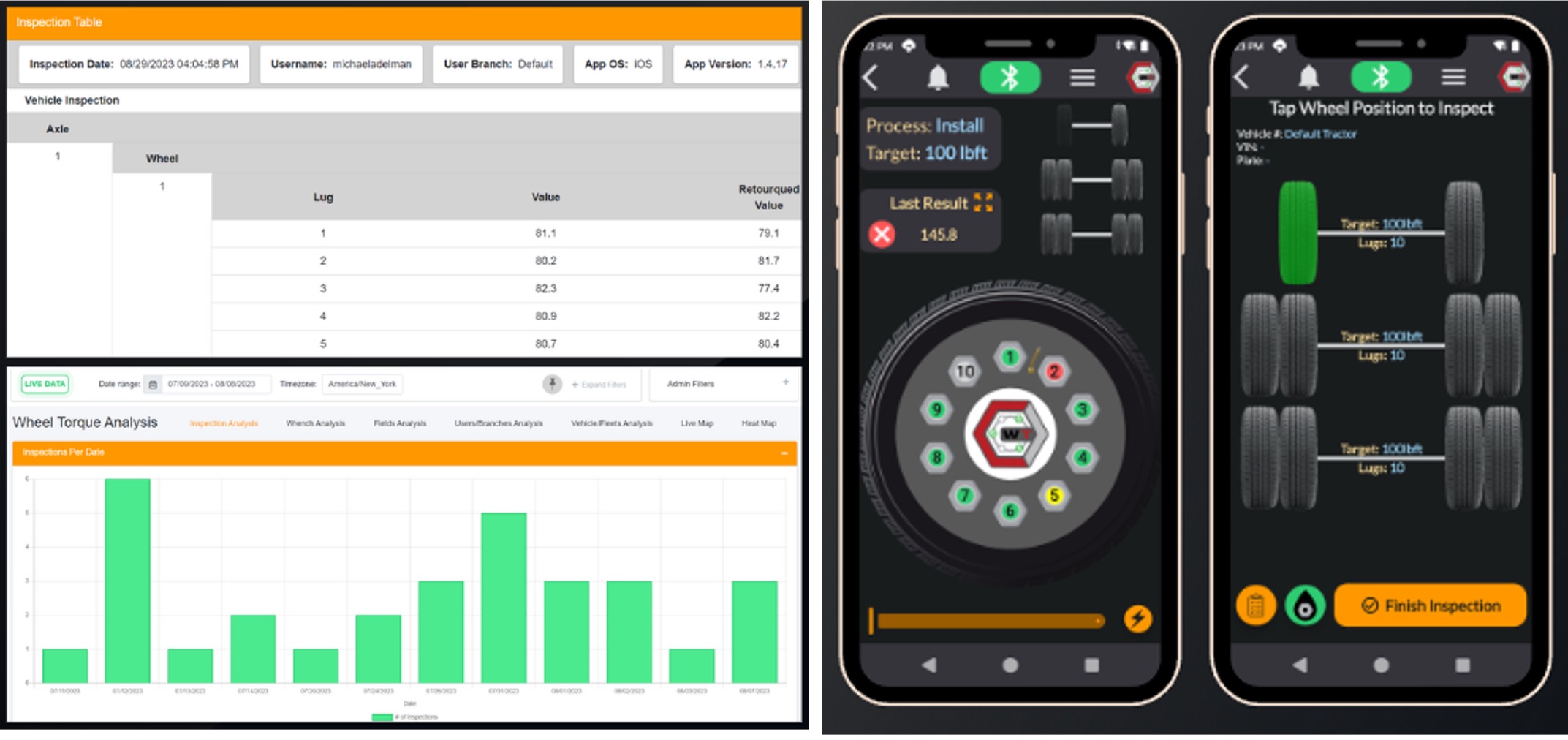

HALTEC DIGITAL TORQUE WRENCHES — PRECISION MEETS CONNECTIVITY

When your operation demands both pinpoint accuracy and digital traceability, Haltec Digital Torque Wrenches deliver. Engineered for professional workshops, fleet service centers, and industrial torque control systems, these wrenches combine advanced sensing, onboard intelligence, and smart networking to elevate your torque control process.

Key Highlights & Features

High Accuracy & Performance

- ±1 % device accuracy ensures your applied torque stays within tight tolerance limits.

- Popular torque device ranges:

- 10–100 ft-lb (3/8″ ratchet, 410 mm length)

- 25–250 ft-lb (1/2″ ratchet, 625 mm)

- 75–750 ft-lb (3/4″ or 1″ ratchet, 1360 mm)

Modular Transducer Design

Haltec offers a modular transducer system. This means that instead of sending the entire wrench for calibration, you can ship just the interchangeable sensor module—saving time, freight cost, and downtime.

Intuitive On-Device Feedback

- Full-color OLED display shows real-time torque reading, units, and progress bar

- Virtual progress bar and audible buzzer guide the operator toward the target torque

- Integrated torque counter alerts you when calibration is due

- Multi-unit support: cNm, Nm, oz·in, in·lb, ft·lb, kgf·cm, kgf·m

Wireless Connectivity & Data Integration

Through Wheel-Torque or API software integration, Haltec establishes traceability across vehicles or assemblies, tracks calibration status, enforces job-specific torque limits, and generates audit-ready reports.

Benefits for Your Operation

- Precision control & repeatability — High accuracy and feedback ensure fasteners are torqued correctly on every use

- Operator guidance & safeguards — Alerts for out-of-spec use and guided torque sequences reduce human error

- Traceable records — Digital capturing and software reporting build audit trails and quality assurance logs

- Reduced downtime & calibration costs — Modular transducers simplify maintenance and speed up calibration cycles

- Scalable wireless architecture — Whether you’re equipping a single bay or a full fleet workshop, wireless integration adapts to your scale

Tips & Best Practices

- Select the proper torque range

Choose a model that comfortably brackets your working torques—avoid under- or extreme over-size. - Utilize modular transducers when possible

To eliminate downtime, stock additional transducers for when the tool equipped transducer is in need of calibration. - Integrate with software early

Establish your torque limits, sequence guides, and data flow before deployment to capture value from day one. - Schedule regular verification

Even digital tools should be periodically checked—Haltec’s calibration rig supports up to 1200 ft-lb. - Train operators

Ensure staff know how to read progress bars, respond to torque alerts, and offload data properly.

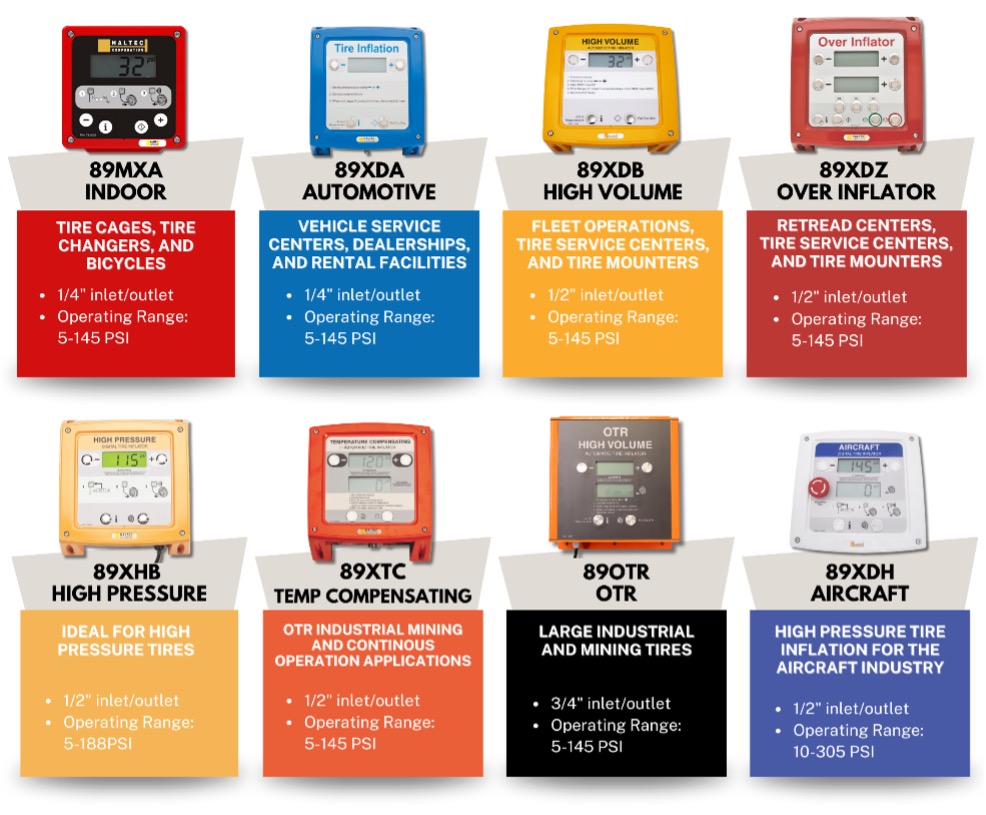

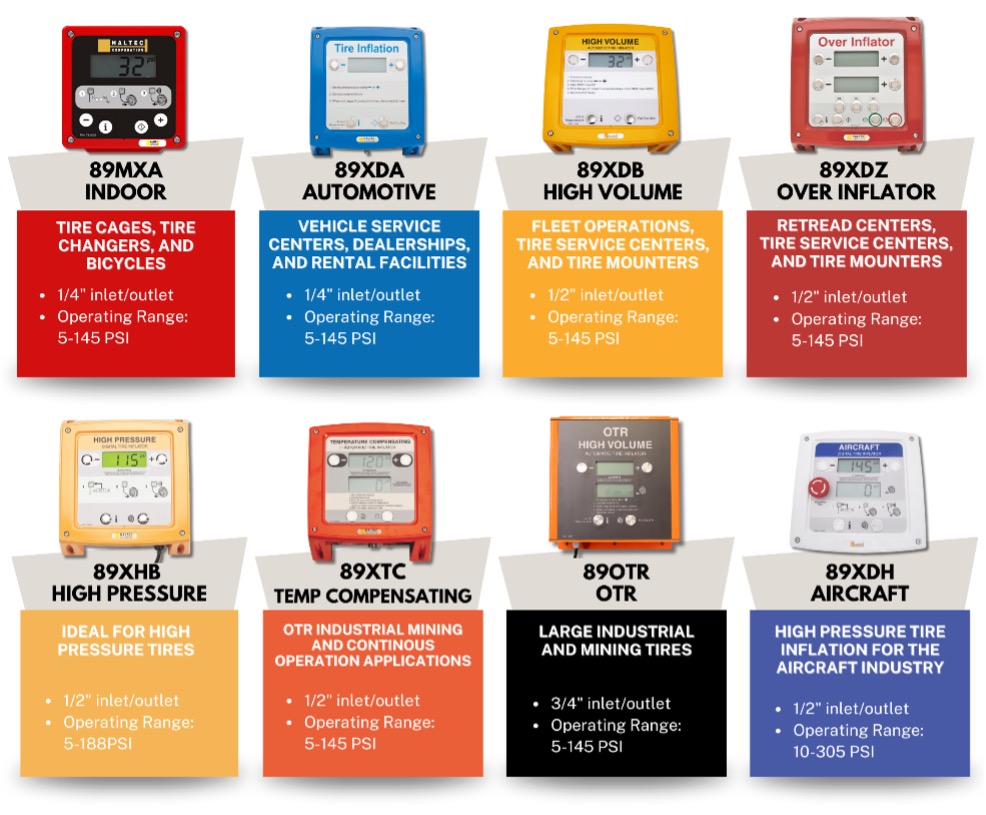

HALTEC INFLATION DEVICES — ENGINEERED FOR EVERY TIRE, EVERY APPLICATION

Since 1970, Haltec has been the trusted name in tire inflation solutions. From single-tire service tools to high-volume OTR systems, our inflation devices are designed to deliver accuracy, safety, and efficiency in every application — mining, construction, trucking, aviation, fleet maintenance, and beyond.

When uptime and performance matter, Haltec inflation devices keep you rolling.

OUR INFLATION DEVICE RANGE

Handheld & Portable Inflators

Compact, rugged, and built for daily use in the field or shop. Perfect for tire service centers, fleet managers, and technicians who need reliability on the go.

- Single and dual-head handheld inflators

- Digital and analog gauge options

- Quick-connect fittings for fast service

Automatic Tire Inflation Systems

For applications where consistency and safety are critical, Haltec’s automatic systems deliver set-and-forget accuracy.

- Pre-set pressure shut-off controls

- Hands-free inflation for shop efficiency

- Options for light-duty passenger tires through to industrial OTR

Heavy Duty & OTR Inflation Systems

Haltec leads the way in inflation technology for the largest tires in the world. Our OTR inflators and safety-engineered systems are trusted in mining and earth-moving applications worldwide.

- Capable of managing the highest air volumes and pressures

- Safety-first design for extreme environments

- Custom solutions available for global mining operations

Multi-Tire Inflation Devices

Cut downtime and improve accuracy by inflating multiple tires at once. These devices equalize pressure across tires simultaneously for balanced, efficient service.

- 2-head to 5-head inflators (used at all 1,200+ Discount Tire locations across the U.S.)

- Ideal for fleet maintenance and high-volume service centers

- Detect and balance underinflated tires quickly

Specialty Inflation Devices

From aviation to motorsports to professional sports leagues, Haltec provides custom precision inflators that go beyond tires.

- Aviation-certified inflation tools

- NFL-trusted football inflation systems

- Specialty applications requiring precise, accountable inflation

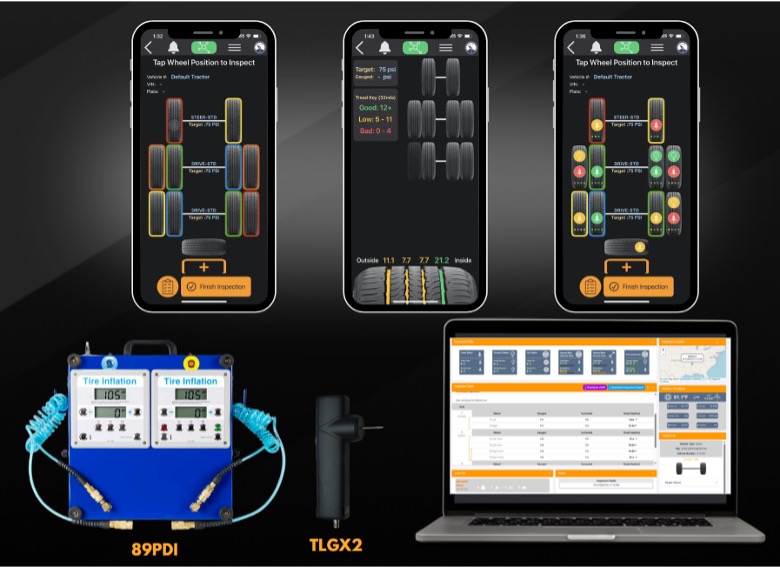

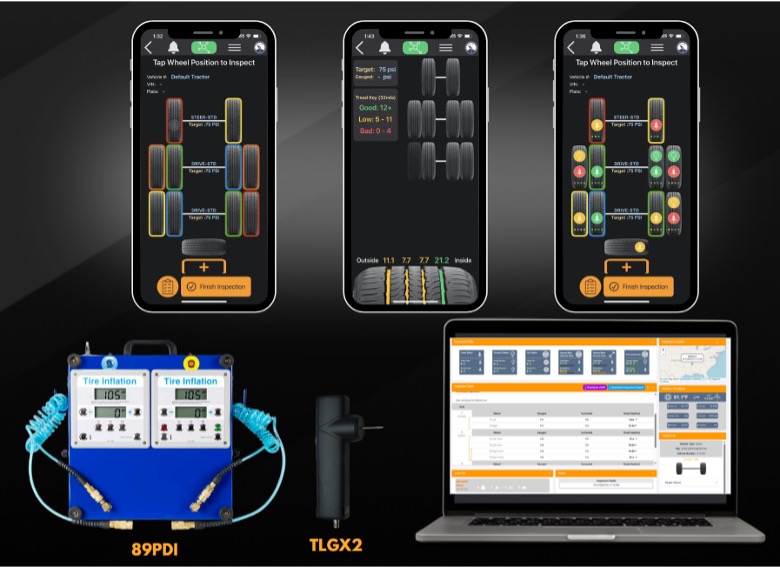

TREAD — TRANSLOGIK INSPECTION TECHNOLOGY SYNCHRONIZING WITH HALTECGO INSPECT

Transense + HaltecGo Inspect

Haltec is the official North American partner for Transense, a global leader in precision sensor, measurement, and tire-inspection technology. We stock Translogik tire inspection tools in the U.S. for expedited orders and quick lead times, ensuring customers get the equipment they need without delays.

The Translogik tire inspection tools provide data-rich, field-ready instrumentation that pairs naturally with the HaltecGo Inspect ecosystem. Together, they deliver unmatched accuracy, accountability, and digital insight across your tire and wheel management program.

How Translogik & HaltecGo Inspect Work Together

- Seamless Data Integration

Translogik inspection readings feed into the HaltecGo Inspect platform, centralizing your tire and wheel analytics. This means pressure, torque, temperature, or condition data—from multiple sources—live in one system. - Broader Application Coverage

With Transense technology, Haltec’s solution suite goes beyond inflation, valve, or torque control. You gain capabilities in condition monitoring, in-service diagnostics, and embedded sensing across rotating parts. - Field-Ready, High Accuracy

Both Transense and Haltec prioritize ruggedness, precision, and consistency in operational conditions. Pairing them gives your customers instrumentation they can trust in real use. - Scalability & Flexibility Whether you roll out a few Translogik handheld units in a regional shop or integrate into a full OEM wheel system, the combined solution scales with your deployment strategy.

Why This Matters to Your Customers

- Unified inspection and control workflows from tire condition to torque to pressure, all under one management umbrella

- Deeper diagnostics and early detection of problems (e.g. temperature rise, torque drift)

- Better traceability and digital reporting across all aspects of wheel / tire maintenance

- A more robust platform offering — one that extends beyond inflation or torque to full wheel health

WHY CHOOSE HALTEC?

- Proven Reliability — Since 1970, Haltec has been the trusted name in tire valve systems, precision inflation equipment, torque tools, and digital monitoring solutions. Built in the USA and trusted worldwide, our products serve fleets, airlines, mines, OEMs, and even professional sports leagues.

- Complete Range of Solutions — From handheld inflators and custom valve systems to large OTR inflation rigs, digital torque wrenches, and connected monitoring technologies, Haltec covers the full spectrum of tire and wheel management needs.

- Precision, Safety & Accountability — Every Haltec product is engineered to provide consistent accuracy and safe operation. Whether it’s extending tire life, standardizing torque, or ensuring inflation accountability, our solutions reduce risk and improve performance across industries.

- Custom Engineering & Innovation — None of these fit your needs? We can customize a solution for you! Our engineering teams specialize in developing bespoke designs — from unique valve configurations and specialty inflators to digital reporting integrations that align with your exact requirements.